Viscosity Reduction for Performance Pipeline Flow

Our preventative treatment pipeline and wellbore maintenance chemical that breaks apart and suspends paraffin wax and asphaltenes.

Pumped continuously to prevent future build-ups, both onshore and offshore.

Biodegradable | BTEX-free | Low Toxicity

HOW IT WORKS

Reacts: LamFlo® reacts with asphaltenes, breaking apart their matrix chains.

Modifies: LamFlo® suspends longer hydrocarbon chains and modifies the asphaltene matrix, lowering the pour point of lower API gravity oils and reducing heavy oil viscosity.

Prevents: LamFlo® will prevent future build-up.

ADVANTAGES

Effective: LamFlo® is aggressive on bitumen and other heavy oils containing high concentrations of asphaltenes. It lowers both the viscosity and pour point of low API gravity oils.

Flexible: LamFlo® has an exceptional environmental profile and low toxicity, making it ideal for both onshore and offshore applications.

Non-hazardous and BTEX-free: LamFlo® is biodegradable, BTEX-free, and non-hazardous when shipped.

Want to know more?

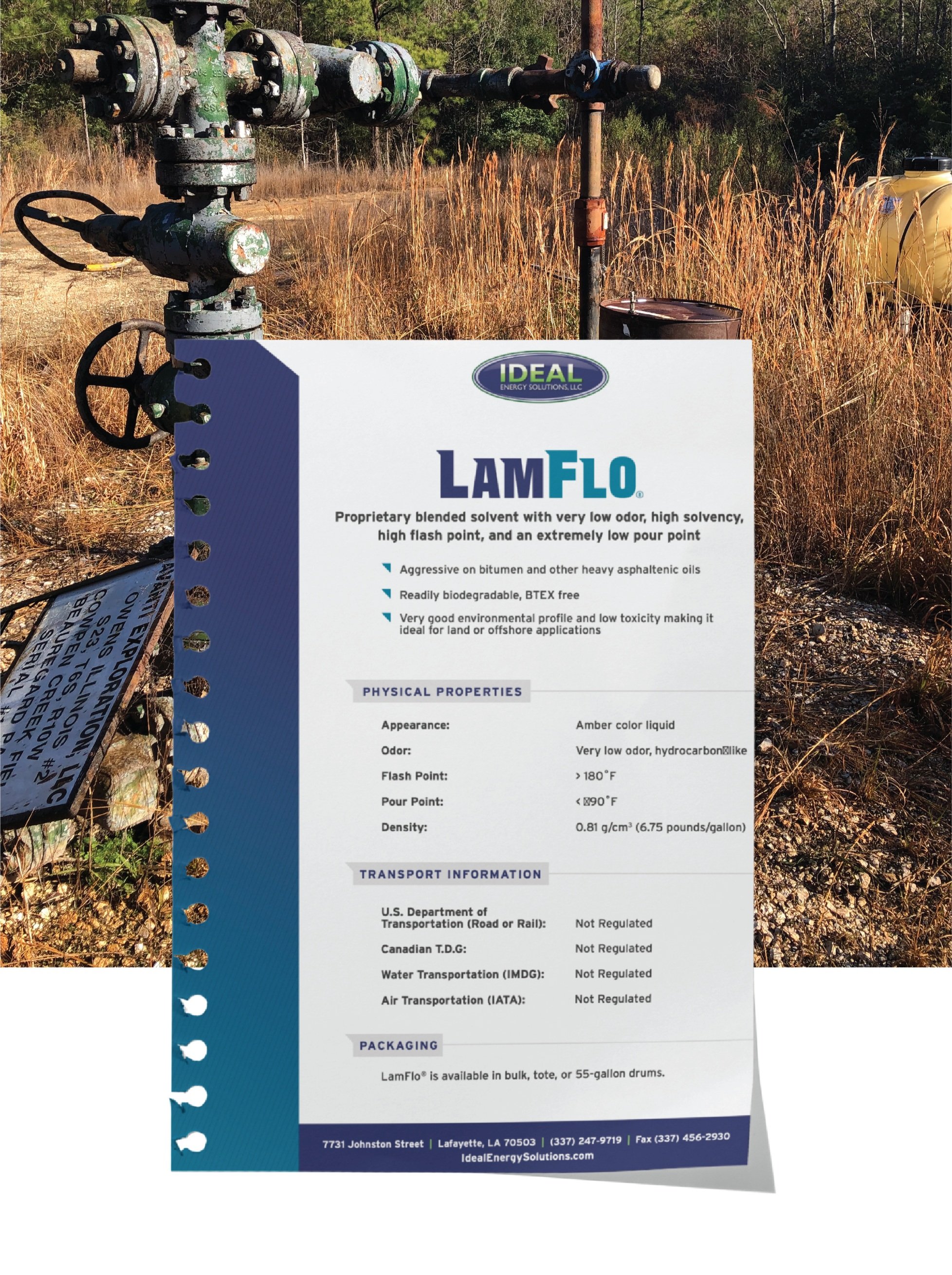

LamFlo® Fact Sheet

Learn more about our preventative treatment technology and how the biodegradable chemical solution can help prevent paraffin wax and asphaltene buildups.

LamFlo® FAQ Doc

Have questions about how LamFlo® can be used on your job? We’ve compiled all the most frequently asked questions into one document.

CUSTOMER SUCCESS STORIES

-

This 4,000-foot stainless steel and Fiberspar flowline was experiencing elevated operating pressures between 700–750 psi. After Tellus installed a new meter in early June, Ideal Energy Solutions LLC began treating the line with LamFlo® at a continuous injection rate. Over the course of five months, the operating pressure dropped steadily to the low 500s, eliminating the need for hot oil treatments and cutting chemical treatment costs in half.